Polyaluminium Chlorides are inorganic polymeric compounds used in various industrial applications. They are also known as PAC, PAK, basic aluminium chloride, polybasic aluminium chloride, aluminium hydroxychloride, aluminium oxychloride, aluminium chlorohydrate, and aluminium hydroxy chloride. The features that differentiate types of Polyaluminium Chlorides include the presence of polymeric species, the distribution of aluminium-containing cation groups, and the degree of polymerization.

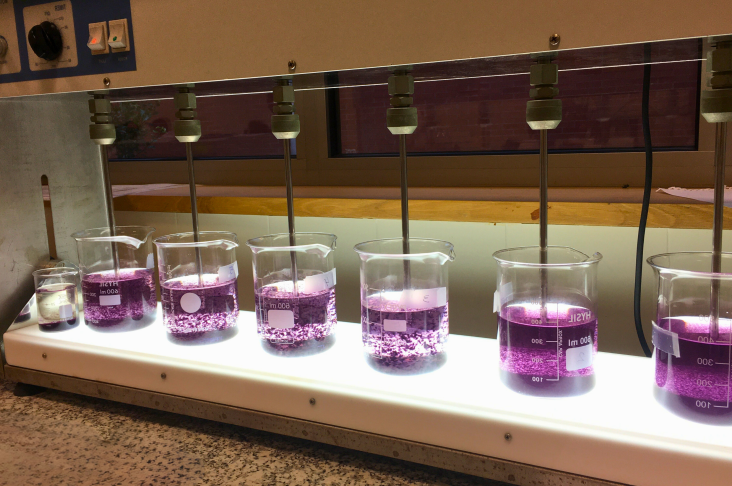

Commercially, Polyaluminium Chlorides have been used as coagulants and flocculants in drinking water and wastewater treatment since the 1970s in Russia, Europe, and Japan, and since the 1980s in the United States.

A wide variety of Polyaluminium Chloride products exist in terms of physical and chemical properties. Although they are generally used in liquid form, they are also available in solid form in the market. In liquid form, they can appear colorless or yellowish, with an appearance ranging from clear to slightly cloudy. At 25°C, their specific gravity ranges from 1.1 to 1.40 g/cm³, and their viscosity ranges from 10 to 50 mPa·s (cp) (in some special types, viscosity can reach up to 10,000 mPa·s).

The general empirical formula for Polyaluminium Chlorides is Alₙ(OH)ₘCl(3n−m), where 0 < m < 3n. The degree of neutralization, or basicity, of hydrolyzed aluminium (Al³⁺) is expressed as the OH/Al molar ratio, commonly denoted as “r.” In aluminium chloride, r = 0, while in aluminium hydroxide, r = 3. For Polyaluminium Chlorides, r typically ranges between 0.5 and 2.5. Another way of expressing basicity is relative basicity, which is the percentage of the OH/3Al molar ratio, generally between 35% and 85%. Polyaluminium Chlorides are always acidic in nature. In some literature or trade names, they are referred to as basic aluminium chloride—not because they are basic, but because they contain hydroxyl (OH) groups.

The total aluminium concentration, which expresses the composition and activity of the products, is given in terms of Al₂O₃. In liquid PACs, the total (active ingredient) Al₂O₃ concentration ranges from 6% to 24%. The presence of inorganic salts such as sodium (Na), chloride (Cl), bromide (Br), and sulfate (SO₄) can contribute to product performance.

The primary performance differences of Polyaluminium Chlorides stem from the diversity of aluminium species in their structure.