Residual aluminum refers to the amount of aluminum remaining in water as a result of incomplete precipitation of aluminum-based coagulants (such as polyaluminium chloride – PAC or aluminum sulfate) used in water treatment processes. High levels of residual aluminum can negatively affect drinking water quality and may lead to long-term health risks. Therefore, effective removal of residual aluminum is essential.

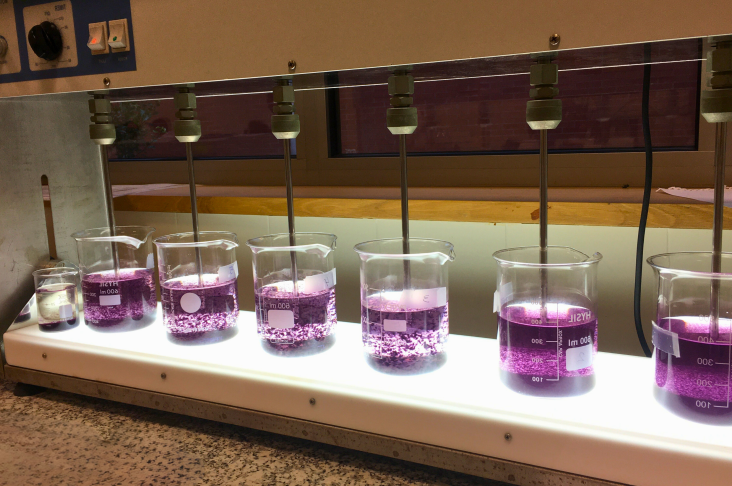

1. Coagulation and pH Optimization

- Accurate adjustment of the coagulant dosage

- Optimizing the pH level (generally in the range of 6.5 – 7.5) to enhance aluminum precipitation

2. Filtration Methods

- Sand Filtration: Captures aluminum hydroxide particles.

- Activated Carbon Filtration: Improves adsorption of organic matter and metal ions.

- Ultrafiltration and Nanofiltration: Separates residual aluminum using high-precision membranes.

3. Chemical Treatment

- Raising the pH with lime or sodium hydroxide can facilitate aluminum precipitation.

- Residual aluminum levels can be reduced using anion exchange resins.

4. Biological Treatment

- Certain microorganisms can capture metal ions through biosorption, reducing aluminum concentrations.

Efficient removal of residual aluminum is critical to ensuring safe water consumption. Implementing the correct treatment processes not only improves water quality but also minimizes environmental and health risks.