Chemicals used in wastewater treatment processes are essential for a clean environment and effective wastewater management. Among the most widely used chemicals in this process are coagulants, which enable the rapid settling of solid particles in wastewater. However, determining the correct dosage plays a critical role in both process efficiency and cost-effectiveness.

What Is the Purpose of Coagulant Dosing?

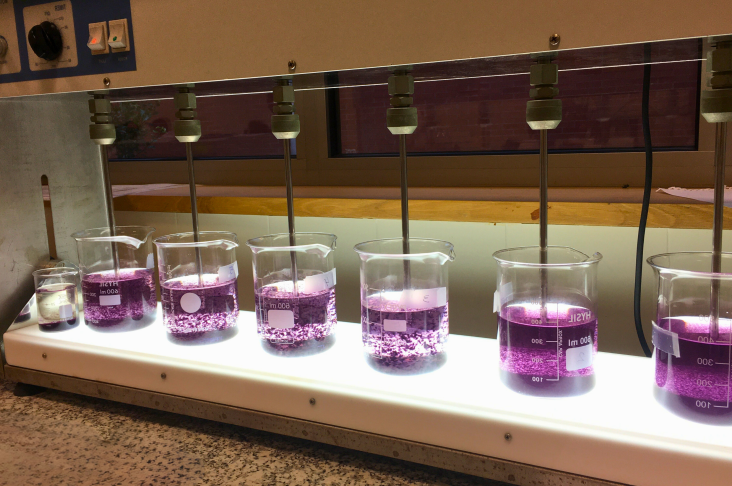

Coagulants help suspended particles in water bind together to form larger clusters. These clusters can then be removed from the water through sedimentation or filtration. Effective coagulation plays a major role in purifying water, removing color, and eliminating dissolved substances.

Determining the Correct Dosage

Every treatment plant has unique water characteristics; therefore, the following factors should be considered when determining the correct dosage:

- Wastewater pollution level: The amount of suspended solids and dissolved organic compounds in the water determines the required dosage.

- Type of coagulant: Various coagulants with different chemical compositions are available on the market, such as aluminum-based or iron-based coagulants.

- pH level: Most coagulants deliver the best results within a specific pH range.

Tips for Efficient Dosing

- Regularly review the dosage rate: As wastewater contamination levels change, it is important to optimize the dosing rate.

- Conduct pilot studies: Small-scale pilot tests can help determine the most effective dosage for improving system performance.

- Use automation systems: Automatic dosing systems continuously monitor the amount of coagulant and allow for quick responses to system changes.

Conclusion

Using the correct coagulant dosage reduces operating costs, enhances environmental sustainability, and maximizes plant efficiency. For more information about the coagulation process and accurate dosing, feel free to contact us.